Before the days of advanced control systems, buildings would be preheated or precooled prior to occupancy using a standard warm up or cool down mode of operation. These primitive sequences would start the air handling units at a set time interval before the building entered into occupied mode. The air handling unit would then operate constantly at some time interval that might range from 30 minutes up to 2 hours until the space zones reach the occupied temperature setpoints. Unfortunately, there are two issues with the standard warm up and cool down mode of operation. One problem is that the time interval may not be long enough. In these cases, the system may fail to bring the zones to occupied temperatures in time, resulting in temperature complaints from occupants as they enter the building. This may be indicative that the air handling system is not started early enough prior to occupancy, or that the outside air damper is opening during start up. In other cases, the spaces could be satisfied in a matter of minutes resulting in the unit operating without reason for the remainder of the time period. Our discussion will focus on this case, which is ideal for savings opportunities.

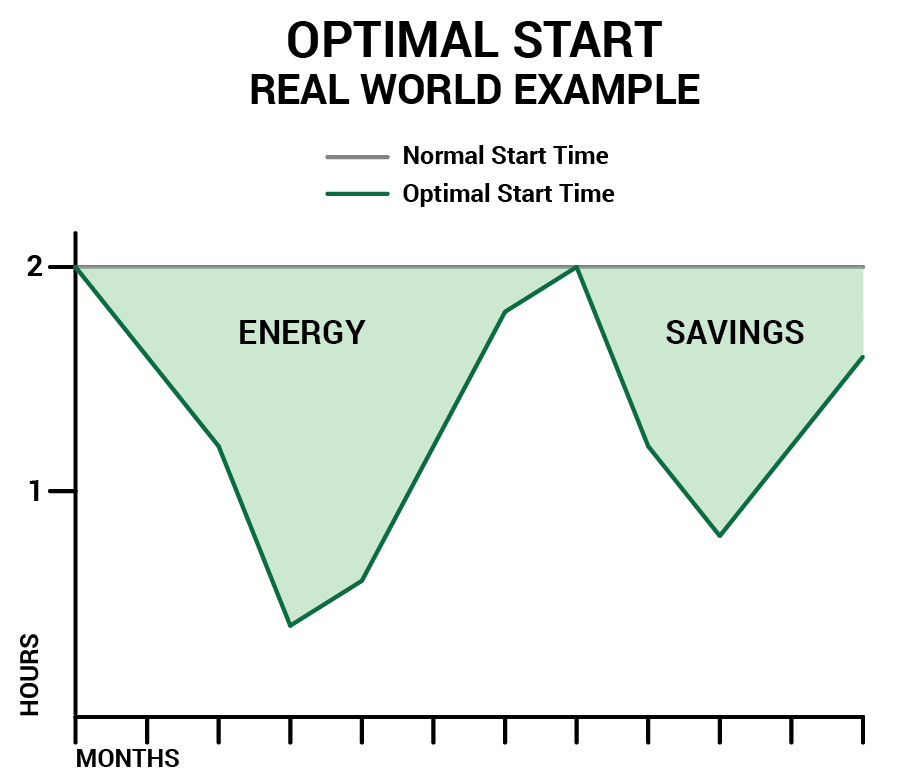

So how can you ensure spaces are comfortable at the start of their occupied schedule without wasting energy? The answer lies in optimal start programming. While every building automation system vendor offers their own “type” of optimal start, they all should accomplish the same thing. An optimal start program is a learning algorithm that will start an air handling system based on how long it has taken to heat or cool a space in the past. Based on historical space temperatures, space temperature setpoints, and outside air temperatures, the optimal start algorithm can recall how long it took to heat or cool a space during similar conditions and make small adjustments until the start time is finely tuned. One of the most important aspects of this strategy is control of the outside air damper. Unless the unit is utilizing “free cooling” (a.k.a. economizer mode), the outside air damper should always remain closed during the optimal start period to avoid wasting energy.

So how can you ensure spaces are comfortable at the start of their occupied schedule without wasting energy? The answer lies in optimal start programming. While every building automation system vendor offers their own “type” of optimal start, they all should accomplish the same thing. An optimal start program is a learning algorithm that will start an air handling system based on how long it has taken to heat or cool a space in the past. Based on historical space temperatures, space temperature setpoints, and outside air temperatures, the optimal start algorithm can recall how long it took to heat or cool a space during similar conditions and make small adjustments until the start time is finely tuned. One of the most important aspects of this strategy is control of the outside air damper. Unless the unit is utilizing “free cooling” (a.k.a. economizer mode), the outside air damper should always remain closed during the optimal start period to avoid wasting energy.

The other side of this strategy is the optimal stop. Optimal stop is less common, yet its application can provide greater energy savings. However, it is important to understand how the spaces served by air handling systems are used and occupied to apply it properly. Similar to optimal start, optimal stop uses a learning algorithm to determine the ideal time allow the space temperatures to drift or “coast” up or down before occupants are scheduled to leave a facility. This reduces the energy consumed by the system without the occupants noticing any changes in the space.

The energy savings of an optimal start control strategy largely comes from the reduction in heating and cooling of the outside air with some savings from fan energy reduction. On a previous project in Connecticut, this was implemented on an air handling unit that supplied approximately 20,000 CFM into the building, 30% of which is outside air. The optimal start programming adjusted the start time of the system within a 2 hour time period. This measure saved approximately $2,000 throughout the course of a year by keeping the outside air damper closed and varying the start time.

This strategy can be combined with many other strategies that we have already discussed or will review in upcoming articles in this retro-commissioning series. Take a look at our other ECM tips here. If you have any questions about this article or think you might be able to apply this strategy in your facility and would like to learn more, please contact us here.

About the Author:

Brian Messerschmidt is a Project Manager at Sustainable Engineering Solutions. He has managed numerous Commissioning and Retro-Commissioning projects throughout Connecticut and Massachusetts. Brian earned his B.S. in Mechanical Engineering from Central Connecticut State University. He is a registered Professional Engineer in the State of Connecticut and a Certified Energy Manager.