The Cool, Dry & Quiet (CDQ) desiccant wheel, trademarked by Trane, has been around for years, however the application and control of this unique device is not well known by most. We’re going to break down how the CDQ wheel works and share some basic control strategies to help you understand it better.

PURPOSE

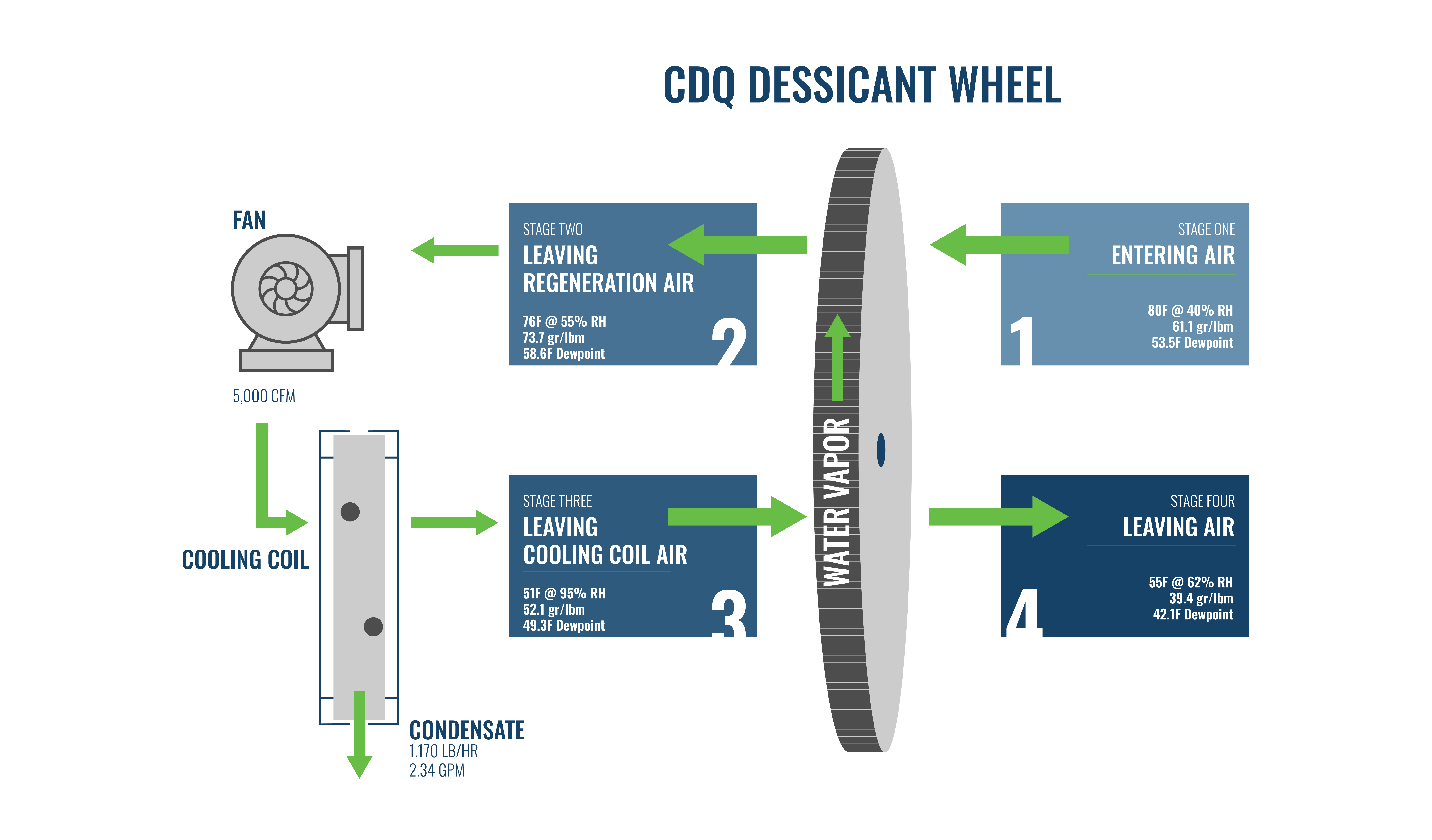

The CDQ wheel is designed to dehumidify an airstream and is more energy efficient than other methods of dehumidification. Typically, a CDQ wheel is installed as shown in Figure 1. The CDQ wheel acts as a means of moisture removal, transferring additional moisture from the supply air back into the incoming airstream to be removed through condensate. The CDQ allows for a lower leaving dewpoint temperature without requiring colder cooling coil temperatures. Located in the supply airstream section of an air handling unit, the CDQ allows for passive dehumidification and reheat without the need for an additional opposing airstream or energy consumption.

CONSTRUCTION

The construction of desiccant wheels includes a variety of materials that have high moisture absorption and desorption capabilities. CDQ wheels specifically are constructed from Type III desiccant (activated alumina). CDQ wheels are typically belt-driven by a motor. They rotate at much slower speeds than a typical energy recovery wheel due to higher surface-to-air ratios. A traditional active desiccant wheel requires both a supply and an exhaust airstream, however the CDQ wheel is unique in that it only requires a single supply airstream.

HOW IT WORKS

Before we dig in, it’s helpful to already have a basic understanding of psychrometrics and how air properties are affected by heating and cooling processes. As a reminder, here are some key definitions:

- Psychrometric Chart: A tool that explains the thermodynamic properties of moist air. A psychrometric chart can be used to identify the dry bulb and wet bulb temperatures of an airstream, along with relative humidity, humidity ratios, enthalpy, dewpoint and specific volume of the airstream.

- Dry Bulb Temperature: The temperature of air measured by a regular thermometer exposed to the air but shielded from direct radiation and moisture. The dry bulb temperature is not influenced by moisture in the air.

- Relative Humidity: A measure of the amount of water vapor present in the air relative to the maximum amount of water vapor the air can hold at a given temperature. The higher the dry bulb temperature, the more water vapor the air can hold. The lower the dry bulb temperature, the less water vapor the air can hold.

- Humidity Ratio: The mass of water vapor present in a unit mass of dry air. The humidity ratio is dependent on the combination of dry bulb temperature and relative humidity.

- Dew Point: The temperature at which air becomes saturated with moisture and water vapor begins to condense into liquid water. This is the temperature at which that condensation will occur on surfaces, as the dry bulb temperature is lowered below what the air can carry in moisture.

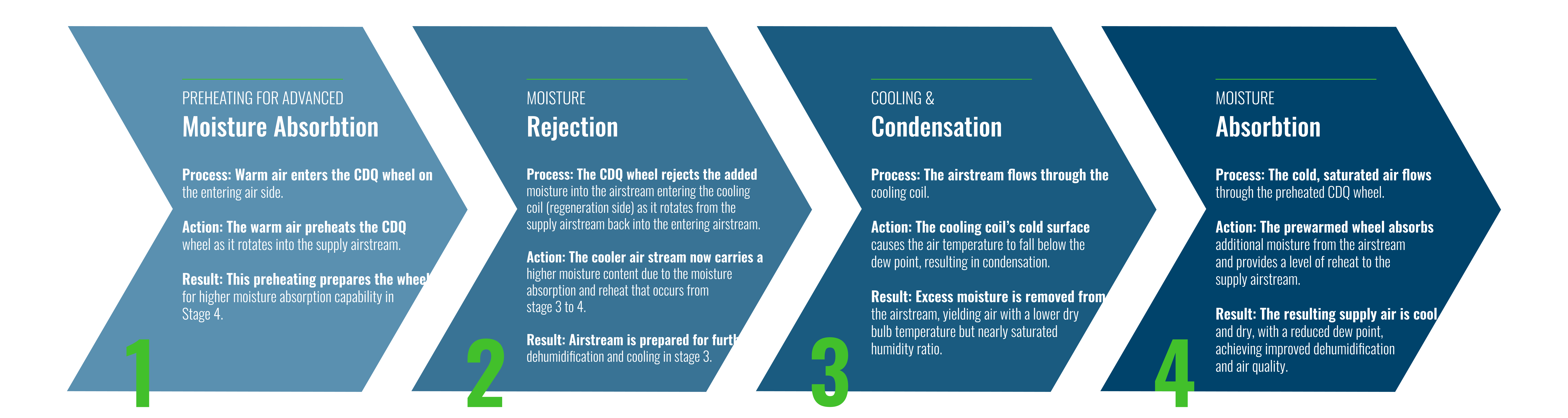

To help break down all the science and engineering, refer to the graphics below and break out your psychrometric chart!

CONTROLS

The controls are fairly simple. Typically, a CDQ wheel is tied to a call for dehumidification in the spaces served by the air handling unit. If a call for dehumidification is enabled, the CDQ is enabled. That’s it! And once the call for dehumidification is satisfied, the CDQ wheel can be disabled. A few tips for best practices are:

- Ensure the CDQ motor status is monitored to confirm operation when enabled

- Provide temperature & relative humidity sensors on each side of the wheel for system feedback and performance verification.

- Perform routine maintenance and performance verification

- Ensure proper filtration upstream of the wheel

- If a preheat coil is provided upstream of the CDQ wheel in the incoming airstream, the controls program can be modified to enable the heating coil and provide additional preheat to the wheel. The added preheat will assist with increasing the wheel’s ability to absorb moisture.

In addition to controls, the manufacturer’s recommendations for periodic inspection, cleaning and servicing should always be followed.

REACH OUT TO SES

Understanding the CDQ Wheel is crucial for optimizing your building’s HVAC performance and energy efficiency. If you need further assistance or have any questions about implementing CDQ wheels, contact Sustainable Engineering Solutions for more information. Our team is here to help you make informed decisions and achieve the best results.

About the Author:

Brian Messerschmidt is a Project Manager at Sustainable Engineering Solutions. He has managed numerous Commissioning and Retro-Commissioning projects throughout Connecticut and Massachusetts. Brian earned his B.S. in Mechanical Engineering from Central Connecticut State University. He is a registered Professional Engineer in the State of Connecticut and a Certified Energy Manager.