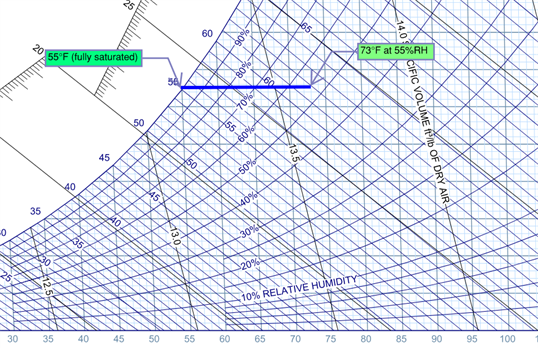

When a multi-zone variable air volume (VAV) air handling system is designed, you might notice that the scheduled leaving air temperature of this unit is about 55°F. Why is that? The 55°F setpoint is based on the typical cooling space temperature and relative humidity (RH) setpoints commonly needed in buildings, which typically ranges from 72°F to 74°F with a coincident RH in the mid 50% range. During the cooling season, when warm, moist ventilation air is mixed with return air in an air handling unit, the mixed air is cooled to 55°F. When cooled to this temperature, some moisture condenses out and the air is fully saturated (nearly 100% RH). However, as the airstream is sensibly heated to 72°F (meaning no moisture is added to the system) by absorbing heat from the occupants and space cooling loads, the relative humidity will fall to around 55% RH as shown on the psychometric chart below. Depending on the outside air conditions and cooling loads, it can be very energy-intensive to cool an airstream down to 55°F. On a design cooling day, this 55°F setpoint is certainly required to overcome the high levels of outside air humidity, but what about the rest of the year when conditions are cooler and dryer?

A supply air temperature (SAT) reset is used to take advantage of the varying heating and cooling load over the course of the year. However, an SAT reset can result in numerous occupant complaints if it is not implemented properly. (For the remainder of this discussion, we are assuming an air handling system that only has mechanical cooling and no energy/desiccant wheel for moisture control.) First, an appropriate SAT reset range should be determined. What are the minimum and maximum SAT setpoints? The minimum SAT setpoint should not be reset below the design condition as colder air will result in cooler surface temperatures on diffusers or other nearby surfaces. These cold surfaces may cause condensation, resulting in stained ceiling tiles and possible mold growth. On the other end, higher SAT setpoints can result in more humidity being introduced into the building. By not cooling the mixed airstream sufficiently (predicated on the air’s moisture content) moisture contributed by ventilation air will not be removed from the airstream, resulting in a warm and muggy feeling for the occupants. Typically, a 55°F to 65°F reset range is effective for most buildings, however, the range should always be fine-tuned to match the space requirements.

Now how should the SAT setpoint be reset? There are numerous approaches to this, however, a trim and response approach (see our Trim & Response Reset article for reference) is usually the best option. It starts with polling the applicable VAV zones served by the air handling unit and monitoring the calls for cooling and heating. Upon startup, the SAT setpoint should always be set to the minimum value. If there are no calls for cooling in the system, the SAT can then be incrementally reset upwards, subject to the maximum allowable setpoint. Additionally, a space humidity high limit should be incorporated to prevent spaces from becoming “clammy”. If at any time there is a call for cooling, the SAT setpoint should then be reset downwards. This is because a VAV box can reduce the amount of cool air delivered to prevent overcooling of the space but cannot cool down the airstream. By making sure an appropriate amount of cooling is available when needed, a properly programmed SAT reset will ensure spaces are satisfied while avoiding wasted energy associated with overcooling the airstream.

Let’s look at a real-world example of the cost savings associated with implementing an SAT reset. At a local university in Connecticut, we found that all of the air handling units were operating to maintain a 58°F setpoint at all times. After implementing a supply air temperature reset, this 105,000 square foot facility was able to achieve approximately $6,500 of annual energy savings with a simple payback of 3.2 years.

This strategy can be combined with many other strategies that we have already discussed or will review in upcoming articles in this retro-commissioning series. Take a look at our other ECM tips here. If you have any questions about this article or think you might be able to apply this strategy in your facility and would like to learn more, please contact us here.

About the Author:

Brian Messerschmidt is a Project Manager at Sustainable Engineering Solutions. He has managed numerous Commissioning and Retro-Commissioning projects throughout Connecticut and Massachusetts. Brian earned his B.S. in Mechanical Engineering from Central Connecticut State University. He is a registered Professional Engineer in the State of Connecticut and a Certified Energy Manager.