Imagine being in your home on a breezy, cool day. You’re cooking in the kitchen, kids are running around the house, and next thing you know, everyone is feeling a bit warm. What do you? Most people would open windows to cool down the house before turning on their home air conditioning system. This, in essence, is what an economizer mode of operation does for an air handling system in a building. Instead of turning on mechanical cooling and consuming energy, the air handling unit would choose to introduce cooler outside air and exhaust the warmer building air. By utilizing economizer mode, spaces can be cooled down without consuming any energy. While the theory is relatively simple, there are a few essential aspects that can cause issues in the building if not properly considered. And unfortunately, these essential items can lead to an economizer mode of operation being disabled if setpoints are not properly vetted. Even when an economizer is appropriately established, degradation of the system due to sensor calibration issues and failed control devices can also lead to an economizer being disabled.

Let’s review the various parameters that can enable the economizer mode of operation. Often, an economizer mode is programmed to enable based on comparing the return air and the outside air dry-bulb temperatures. This is known as a comparative dry-bulb economizer. While this is better than having no economizer, this method doesn’t consider the relative humidity, or enthalpy, of the airstreams. Humidity, which is the amount of moisture in the air, is an indicator of the air’s overall total heat content. The total heat content of air is comprised of two parts: the sensible and latent heat content. The dry-bulb temperature of air is the sensible heat content of air and the moisture energy content is known as the latent heat of air. This total heat content is also called enthalpy. When trying to cool a space, enthalpy should always be considered to account for both sensible and latent loads. To clarify this further, imagine a scenario where an air handling unit enters an economizer mode during a cold but rainy day. While the outside air may be 5 to 10°F cooler than the space temperature, it has a higher moisture content and thus could have a higher total energy load. Trying to economize with this outside air condition would introduce cool, moist air into the building. Not only would this result in human discomfort, but may also lead to other issues including damage to indoor absorptive materials and possible mold growth. To avoid this situation, a comparative enthalpy program is typically implemented.

Another aspect to consider is what happens to the space or building air pressure when an economizer mode is enabled. As more outside air is brought in to cool the area served, the space pressure could being to increase. If the excess outside air is not equally exhaust, the positive pressure could build significantly causing doors to open, induce drafts, create air noises such as whistling at doors or windows, and possibly cause migration of odors from one area to another. To account for this over-pressurization, a proportionate amount of air should always be exhausted out of the building simultaneously. As such, space pressurization is another factor to consider when implementing an economizer mode of operation. As a general rule, the exhaust airflow should be slightly less than the introduced outside airflow to maintain a neutral to slightly positive building pressure.

Lastly, mechanical cooling should always be allowed to operate as the second stage of cooling during economizer mode. If the outside air damper is 100% open and there is still a need for cooling, the mechanical cooling coil should be allowed to operate to satisfy the space conditions. Having the cooling coil operate as a second stage to the economizer operation reduces the overall load for mechanical cooling, thus reducing the energy consumed while still satisfying the requirements of the space. If second stage cooling is not allowed, the space conditions may never be satisfied.

During building walkthroughs, one of the first things that should be reviewed for any air handling system is the economizer mode of operation. We usually find that an economizer mode has been locked out for a variety of reasons and can be corrected and further optimized. By looking at the space requirements and condition of the air handling unit, a fine-tuned economizer mode can result in substantial savings at a very low implementation cost. In a previous retro-commissioned facility, approximately $2,700 of annual savings were achieved by simply fixing some failed damper actuators and fine-tuning the economizer enabling setpoints on four air handling units.

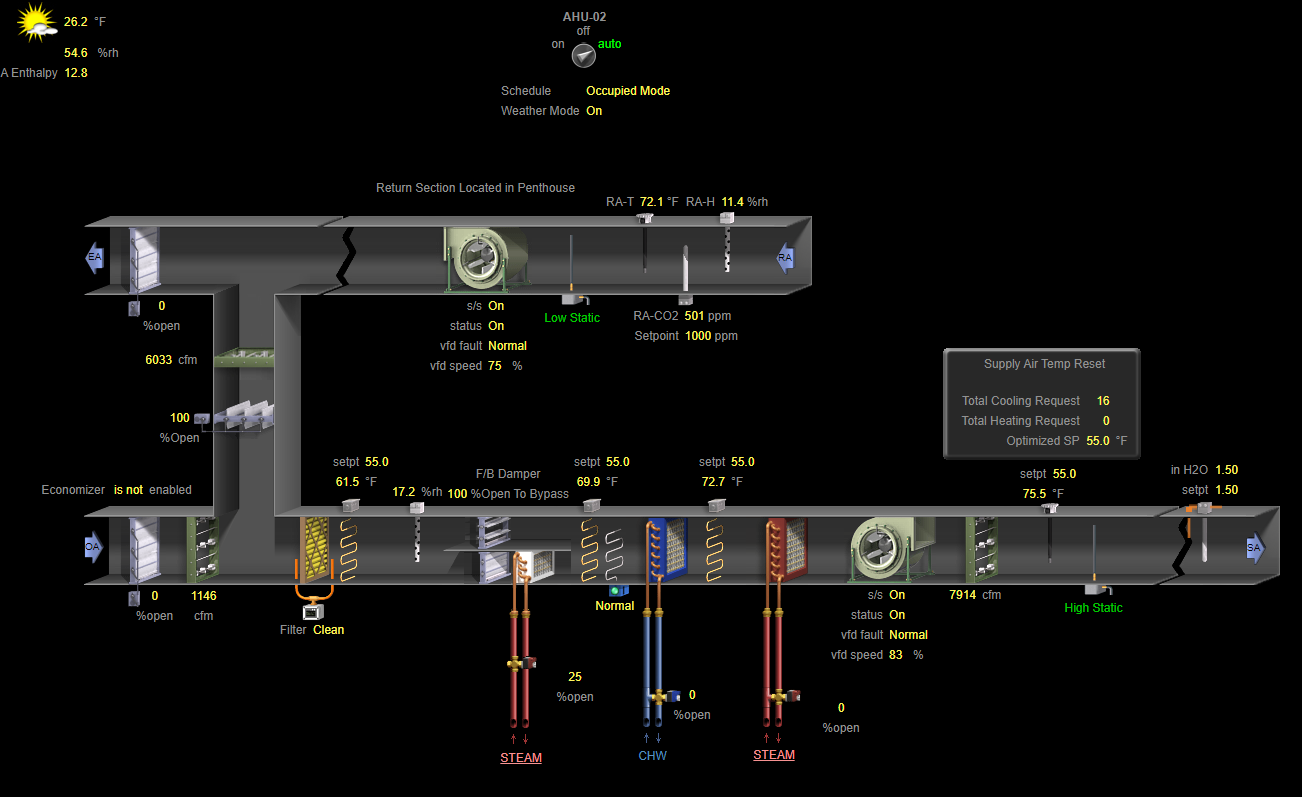

Failed economizer controls preventing free cooling from taking place.

This strategy can be combined with many other strategies that we have already discussed or will review in upcoming articles in this retro-commissioning series. Take a look at our other ECM tips here. If you have any questions about this article or think you might be able to apply this strategy in your facility and would like to learn more, please contact us here.

About the Author:

Brian Messerschmidt is a Project Manager at Sustainable Engineering Solutions. He has managed numerous Commissioning and Retro-Commissioning projects throughout Connecticut and Massachusetts. Brian earned his B.S. in Mechanical Engineering from Central Connecticut State University. He is a registered Professional Engineer in the State of Connecticut and a Certified Energy Manager.