Non-residential facilities typically have multiple cost components on their electric energy bills. The two largest components are the consumption charge (kilowatt hours consumed over the billing period) and the demand charge. The demand charge is based on the amount of instantaneous power the building draws at any given time, typically within any 15-minute period during the peak hours of the day.

Depending on the utility rate structure that applies to the facility, peak electricity demand may account for 30% or more of an energy bill. What may be less clear on an energy bill is the peak electricity rachet structure that applies to the demand: a utility company may charge each month for the highest demand within an eleven-month period, meaning a single hot day in August determines the peak demand charge for the remainder of the year. Buildings and facilities with shorter-than-annual demand rachet periods will have different strategies within those periods, i.e. fall, winter, and spring seasons, to reduce demand.

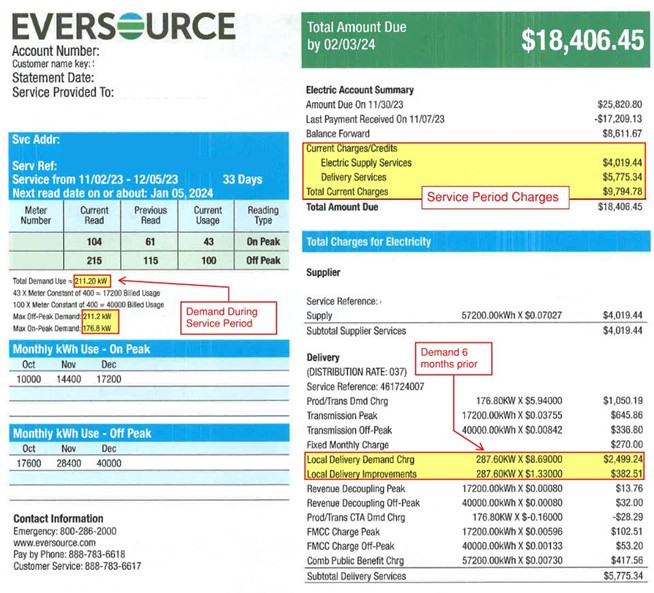

The image of the utility bill below shows the various components of the bill and the demand costs associated with the period.

Investigation

With so many possible factors at the root of high peak energy demands (not to mention the complexity of the electricity bill in general), an investigation into the peak electricity demand from HVAC equipment in a building, which averages +40% of total building energy use(1), can reveal effective opportunities to reduce peak demand charges over the course of the entire year.

The first step in determining whether an in-depth investigation is needed is to review the monthly electric utility billing data (over several years if possible). If the peak demand is discovered in unexpected months, or is rising every year, it’s worth reaching out to a Certified Energy Manager or Certified Energy Auditor. These professionals are specifically trained in identifying opportunities for optimizing system performance. An investigation into the peak demand event, even if that event is occurring when expected, can yield thousands of dollars in energy savings.

Through experience, we know that HVAC equipment accounts for significant electrical use and demand for most buildings. Quite often the peak energy demand from HVAC systems occurs during late July or August as cooling demands from air conditioning systems reach their highest point in the year.

Industrial facilities may have demand peaks unrelated to seasonality based on the industrial electrical loads needed to run manufacturing equipment. As a result, a different focus is required to find the primary cause of these high electricity demands. However, even if HVAC loads are smaller in comparison to manufacturing electrical loads, optimizing the HVAC electrical demand will still yield significant savings.

Note: With the industry-wide migration away from fossil fuels and towards electrification of heating systems, building electric energy use is increasing during the cold months. This migration is causing a shift in annual peak electrical energy demand events from summer cooling to winter heating months in some buildings.

BMS Programming Changes and Adjustments

What can be done within the building management system to help reduce the peak electricity demand caused on one day? After discovering the cause of the peak demand, solutions could range from something simple, such as tailoring the BMS programming for specific equipment, to implementing more comprehensive system-wide BMS programming modifications to optimize HVAC equipment performance.

One of the most effective ways to ensure HVAC equipment is working optimally and reducing peak demand during critical times is either monitoring-based commissioning, if your facility has already been equipped with a building automation system capable of trending HVAC system data over time, or retro-commissioning.

There are plenty of options for reducing peak electricity demand, but each solution will differ from one facility to the next. A few scenarios we see are:

- A school is experiencing high demands during those hot summer days. An investigation into building use may reveal sections of the school that are not occupied during summer which can have a separate summer Schedule or an improved Supply Air Temperature Reset that more closely fits the needs of the school.

- A new office building equipped with heat pump heating is experiencing high demands on January mornings. A review of the building systems trend data revealed that all of the equipment is starting at exactly the same time in the morning. By implementing a staggered start routine (enabling of HVAC equipment without VFDs at different times) or implementing Optimal Start programming, the simultaneous high power draw is avoided, thus reducing peak demand.

- An existing building experiences extreme electrical demand after power outages. When HVAC systems revert to normal operation after power outages, there can be significant calls for electricity, especially when fans and pumps are not equipped with Variable Frequency Drives (VFDs) for soft start. Incorporating a staggered start program is a solution, but installing VFDs and the energy savings associated should be investigated as well.

- A medical facility has higher summer electrical demands each year but operates on a 24/7 basis. This building may need retro-commissioning to optimize air handling systems, ventilation loads, chiller, cooling tower, and other systems programming.

Additionally, for facilities that can be flexible with energy use during the high peak demand times mentioned, it is worth contacting the utility company to inquire about any demand-response programs. Proper BMS programming can make it easy for facilities to participate in the program and get paid by the utility company to participate.

Other Peak Electrical Demand Reduction Techniques

There are additional ways to reduce energy demand during peak times, such as a thermal storage system. Ice thermal storage, phase change material thermal storage, or chilled water storage are systems that generate ice, freeze specialized materials, or chill a volume of water overnight during off-peak hours, respectively. These systems are used in conjunction with the building’s standard cooling system, to air condition spaces during normal daytime hours like hot summer afternoons. Thermal storage methods are effective in climates that have significant cooling needs.

Electrical batteries are another energy storage technique that can help reduce peak loads in times of high demand. Unlike thermal storage applications, electrical batteries can be used for a wider range of applications like heating or lighting. Batteries can be charged during periods of low-demand or in conjunction with on-site renewable energy systems and discharged during peak and high-demand periods.

Thermal and electrical storage technologies don’t have the added benefit of reducing energy usage that optimized programming of HVAC equipment typically has. Instead, these systems shift the electrical use from peak times to off-peak times. It is important that these systems are rigorously commissioned to ensure the installed systems reduce the peak loads as intended.

Where to Begin

If it is unclear whether an investigation makes sense for the facility, retro-commissioning will benefit the facility’s overall energy consumption, maintenance costs, and occupant comfort in addition to reducing the peak load of the building. Reading the “Signs you might need Retro-Commissioning” section of our What is Retro-Commissioning article would be a great place to start.

(1) US General Services Administration

About the Author:

Will Belke is a Commissioning Engineer serving SES’s Massachusetts and Rhode Island projects. His expertise spans system and whole building commissioning projects, with a keen eye for ensuring high performance and sustainability standards are met. Will is a LEED Accredited Professional and Certified Energy Manager.